Battery Fires: How Poor Maintenance and a Simple Boost Can Ignite a Catastrophe

By the IGNISOC Fire Risk & Investigation Team

Premier Specialists in Vehicle Fire Analysis and Risk Mitigation

In today’s complex vehicles, batteries are more than just a starting system—they are power hubs, communication gateways, and in some cases, the source of a dangerous fire. While most owners focus on fluids, brakes, or tires, the battery is quietly sustaining all electronic systems—and when overlooked, it can become a serious ignition risk. This is especially true when a vehicle sits unused, suffers poor maintenance, and is then suddenly brought back to life with a jump-start.

At IGNISOC, we’ve investigated hundreds of electrical fires, but a recent case perfectly illustrates how battery condition, improper boosting, and minor oversights can result in a severe thermal event. The lessons drawn from this incident apply to all vehicles, whether powered by gasoline, diesel, or hybrid systems.

The Fire: A Case of Boosting Gone Wrong

In this case, the vehicle had been stored with minimal use and lacked recent service history. After sitting idle, the battery was depleted and required boosting to start the engine. Upon application of a jump pack, the positive terminal (B+) immediately overheated, generating enough heat to soften the lead post, melt surrounding plastic, and damage the nearby Intelligent Battery Sensor (IBS). A burned wrench was found in the battery compartment, suggesting that arcing—possibly accidental—may have contributed to the ignition.

The fire did not originate from fuel, engine heat, or an external source. It was entirely electrical.

The failure point was traced to the B+ terminal where the cable meets the battery post. In a healthy system, this junction carries high current safely. But in this case, corrosion, a possible loose clamp, or hidden internal degradation created resistance. When current from the boost surged through the degraded connection, resistance heating ignited surrounding insulation.

Compounding the danger, the battery likely vented hydrogen gas, which is colorless, odorless, and highly explosive when trapped in confined spaces like a rear battery compartment.

Understanding the Battery Architecture

Modern vehicles with rear-mounted batteries route high-amperage cables from the under-hood booster post to the rear battery compartment. These cables feed critical systems such as:

- Starter motor

- Alternator charging circuit

- Power distribution box (PDB)

- Comfort modules and fuses

These components pass through a battery terminal housing that includes high-current fusing, safety disconnects (pyrofuses), and IBS sensors. Any resistance at these interfaces—especially when boosting—can produce dangerous heat levels.

Why Battery Health Matters

Modern AGM and flooded lead-acid batteries are designed to last—but only if they’re kept fully charged and periodically tested. When a vehicle sits unused for months, especially in fluctuating climates, batteries can sulfate internally. This condition increases resistance, weakens the charge-holding ability, and makes the battery prone to outgassing and terminal heating during cranking or boosting.

It doesn’t matter if the battery is brand new or several years old—once the chemistry is compromised, the risk rises quickly. And boosting a compromised battery is like trying to pump water through a kinked hose under pressure: energy will build up at the restriction point, and in electrical systems, that means heat.

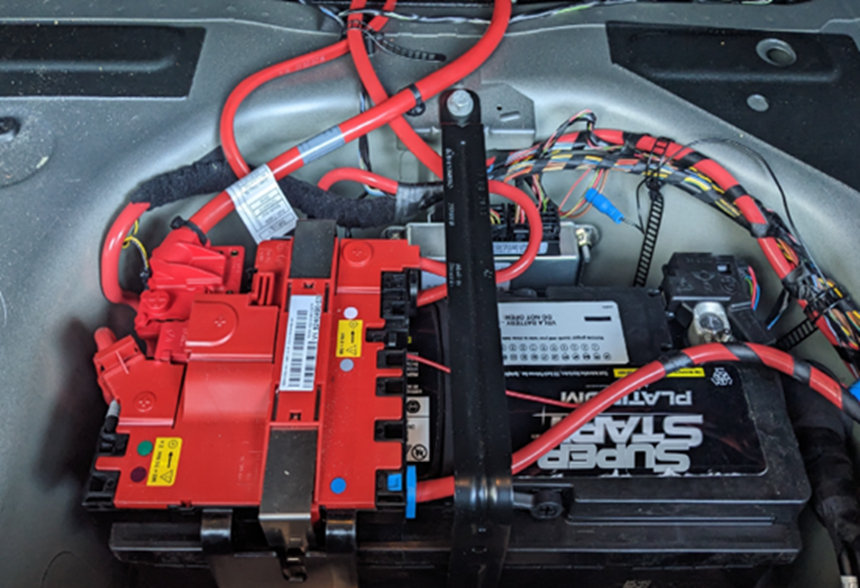

This red plastic housing contains:

Main B+ (positive) power distribution point with Integrated fuses for downstream circuits and high-current fusing and relay protection with an explosive disconnect (pyrofuse) for crash response. Inside are:

- Fused high-current feed to the Power Distribution Box (PDB) under the hood

- DME/ECU power feed

- Charging system return

The Topmost red cable exiting forward in the exemplar image (upper right) is the main B+ cable to the engine bay, likely feeding:

- Starter motor

- Alternator charging return

- Jump-start terminal

- Power Distribution Box (PDB)

Side-branching red cable likely feeds interior fuses, comfort modules, or the rear fuse block.

Given the complete destruction of the B+ terminal housing, and the localized melting of the lead post, the evidence strongly supported a scenario which was initiated by electrical arcing during the jump-start process. The act of jump-starting introduces high transient currents, and any accidental short which would rapidly generate intense heat and result in plasma arc formation. This arc would have been sufficient to ignite vented hydrogen gas from the battery, particularly if internal pressure had built up due to overcharging or internal failure.

The rapid onset of thermal degradation at the B+ connector, the evidence of lead melting (indicative of temperatures >327°C), and the immediate ignition of adjacent synthetic materials are consistent with an arc-induced ignition rather than a slower failure under regular engine charging loads. Furthermore, the damage was localized and asymmetric, with no significant evidence of progressive cable heating away from the battery, which would have been more characteristic of a resistive failure during regular engine operation

Preventing the Preventable: IGNISOC’s Commitment

This case—and many others like it—are entirely preventable. At IGNISOC, we work with fleet operators, insurers, and the public to provide evidence-based fire investigations, mechanical failure assessments, and risk mitigation strategies. Our findings don’t just determine origin and cause—they help prevent future losses.

Here are key preventative measures for vehicle owners and operators:

- Keep batteries fully charged—especially in long-term storage. Use a smart maintainer.

- Inspect terminals for corrosion, looseness, or heat damage.

- Avoid leaving tools or loose metal objects in battery compartments.

- Never boost a battery without verifying its condition.

- Replace aging or deeply discharged batteries, even if they seem to recover after a charge.

Conclusion: The Hidden Power of Prevention

Vehicle fires don’t always begin with smoke or noise. Sometimes, they start silently—through heat, gas, and a spark at a terminal no one’s touched in months. This case proves that even a single weak connection—hidden beneath a battery cover—can escalate into a vehicle loss and put lives at risk.

At IGNISOC, we’re committed to uncovering these failures before they repeat. Through expert analysis, proactive risk management, and education, we help vehicle owners and operators eliminate electrical vulnerabilities before they ignite. To learn more about battery fire risks, electrical diagnostics, and our case studies, subscribe to our newsletter or explore more articles in our resource hub.